ATLAS Tracker Upgrade

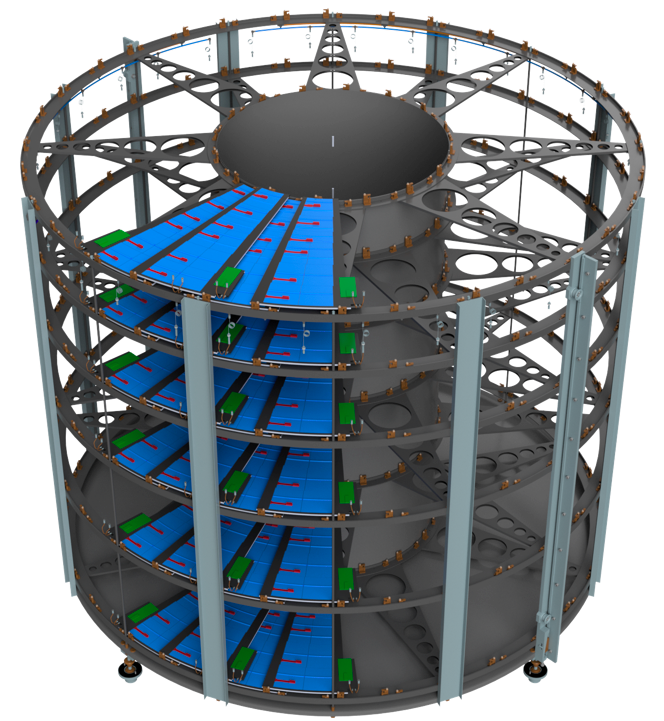

The ATLAS group at IFIC-Valencia is heavily involved in the upgrade of the central tracking system of the ATLAS experiment for the operation at the High Luminosity LHC (HL-LHC). The the High-Luminosity LHC operation, Phase-II, will enable ATLAS to fully exploit the increase in Luminosity at LHC planned for 2022. The upgrade of The new tracking system will consist of a pixel detector at small radius close to the beam line and a large area silicon strip tracker surrounding it, with a silicon area of about 165 m2. The silicon tracker system has three parts: a central barrel region and two endcaps. The strip barrel consists of four cylinders of 2.8 m each that surround the beam-line. The strip end-caps have six disks on each side to provide full coverage.

The basic mechanical building block of the barrel is called the stave and petal in the endcap. These units, also called local supports, consist of a low mass central stave/petal core that provides the mechanical rigidity, support for the modules and houses the common electrical, optical and cooling services. It also provides the accurate alignment and fixation points. The four barrel layers consist of 392 staves with sensors on both sides. Each endcap disk is populated with 32 identical petals. The staves and petals are loaded into global structures that provide the final location of the sensors and the rigidity of the system.

We have been conducting a very intense R&D program to determine the best sensor technology for the silicon strip tracker since the times of the ROSE collaboration that later, in 2001, became the RD50 collaboration. Although the baseline technology for the sensors of the new tracker was chosen back in 2007, we continue the R&D on sensors for the future trackers within the RD50 collaboration.

The group also participates in the design and characterization of the readout electronics of the sensors for the endcap. A small petal, the petalet, was first prototyped to address the issues that differentiate petals from staves in the barrel.

We also work on the design of the local (petals) and global structures that hold the petals. This includes finite element analysis (FEA) of the structural properties of the system and validation of the models. We also work the design of the service ducts that bring control signal, power and cooling to the petals and bring back data and environment monitoring signals.